ABOUT US

JiangHuai Building Materials Technology

Wuxi JiangHuai Building Materials Technology Co., Ltd. is a high-tech private enterprise integrating the research, design, production, sales, construction and after-sales service of new wall materials, grouting materials, special cement, polymer special mortar and concrete admixtures.

Main business: Building, infrastructure, industrial, mining, marine engineering, military engineering, expressway, tunnel, bridge, concrete repair, installation of large-scale mechanical equipment, wind power equipment, foundation bolt fixing, etc. High-performance, early-strength, micro-expansion, self-compacting, large-flow leveling, rapid repair cement grouting material

Founded in

Technical personnel

Cooperation cases

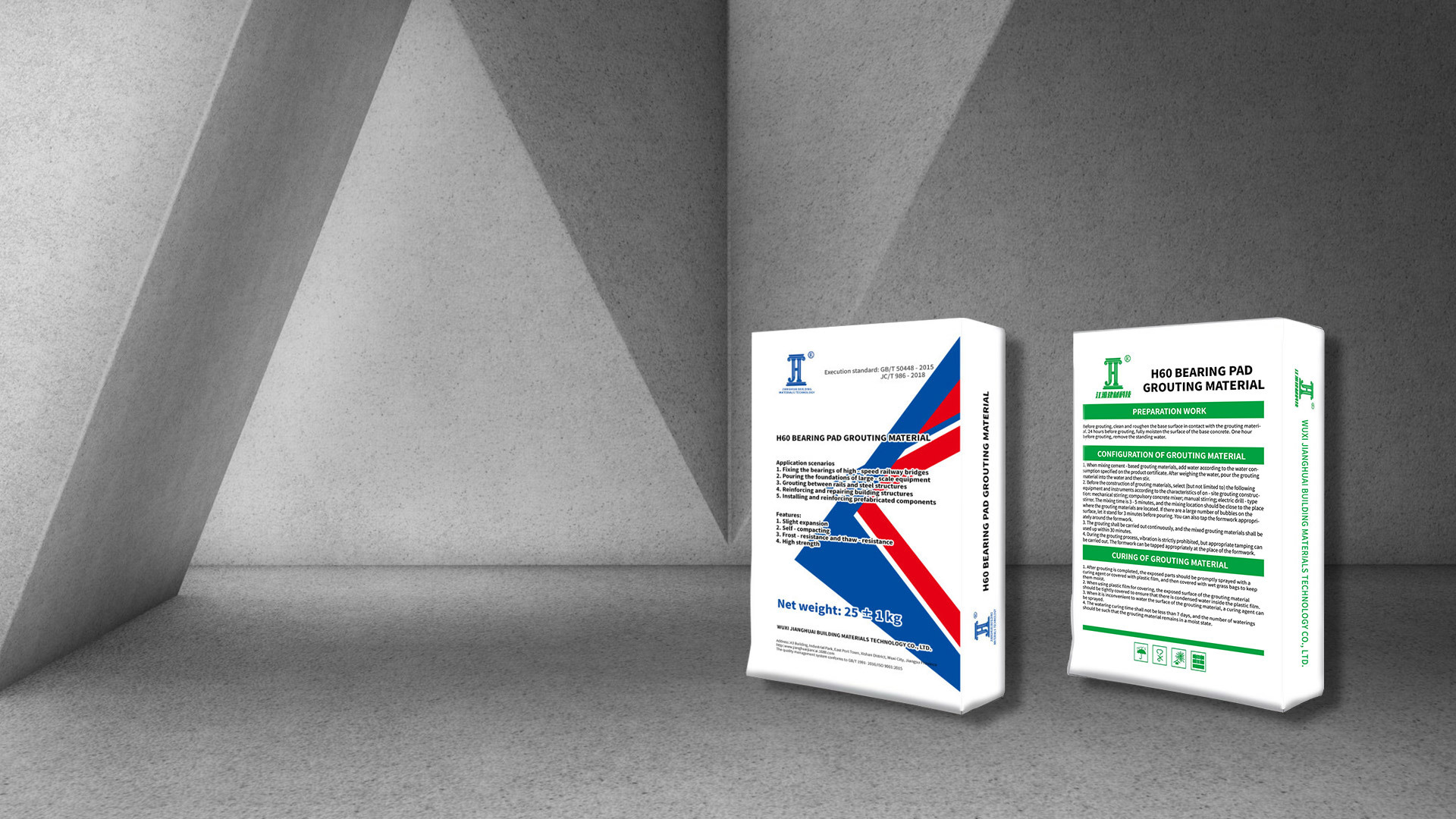

PRODUCTS

To build a national benchmark in the industry of new wall materials, grouting materials, special cement, polymer special mortar and concrete admixtures, and to actively provide high-quality services to our customers.

HONORS

Currently, the company has 20 employees, 3 engineers, and 12 senior technicians. Two lines of fully computer-controlled zero-gravity mixing equipment and a standard laboratory. The annual production capacity is 200,000 tons. At present, our company has applied for two invention patents, one utility model patent, and two appearance design patents. The advantages of technological achievements transformation are obvious, and the future development is full of potential.

MORE +

Innovation and Cooperation

Customer's Reliable

To build a national benchmark in the industry of new wall materials, grouting materials, special cement, polymer special mortar and concrete admixtures, and to actively provide high-quality services to our customers.

Supported by a professional team (3 engineers + 12 senior technicians), equipped with a standard laboratory and 6 patents, efficient technology transformation, fast product innovation and iteration, and sufficient development potential.

VIEW MORE

24-Hour Rapid Response + Delivery Guarantee

The fully computer-controlled production line has an annual capacity of 200,000 tons, with advanced equipment and mature processes. Standardized production ensures quality, and the large-scale supply capacity is industry-leading.

VIEW MORE

Over 10 years of specialized production experience. High strength, consistent quality. Comprehensive ISO and qualification certifications. Large capacity, fast delivery. Custom formulations & technical support. Global export & long-term cooperation.

VIEW MOREBLOG

2026-03-07

Unlocking the Benefits of Quick Hardening Cement: A Modern Solution for Construction

2026-03-04

Top Reasons to Choose Sulphoaluminate Cement for Your Next Project

2026-03-01

The Marvels of White Portland Cement: Enhancing Aesthetics and Performance in Construction