PRODUCTS

CGM-140 Explosion-Proof Concrete

Main business:Building, infrastructure, industrial, mining, marine engineering, military engineering, expressway, tunnel, bridge, concrete repair, installation of large-scale mechanical equipment, wind power equipment, foundation bolt fixing, etc. High-performance, early-strength, micro-expansion, self-compacting, large-flow leveling, rapid repair cement grouting material

- Commodity name: CGM-140 Explosion-Proof Concrete

- Description

-

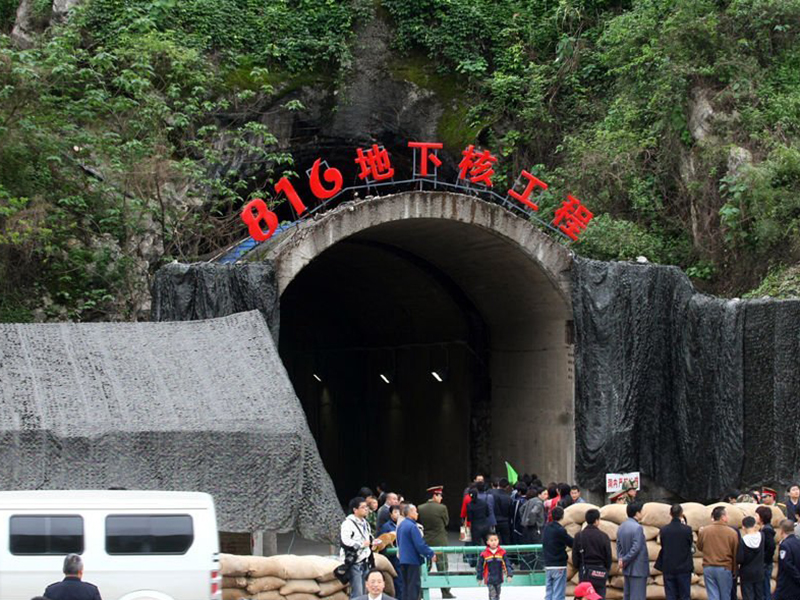

Specifications 25kg/bag Model CGM-140 Packaging Material Three paper and one film Shipping Method Jumbo bags Shipping Time Consult the freight forwarder Shelf Life Six months FOB Price $1850/ton MSDS Yes Payment Method Telegraphic Transfer Storage Keep away from rain or moisture Application Scenarios Features: 1. Military and defense projects 1. Impact resistance 2. High-risk facility protection 2. Blast resistance 3. Public counter-terrorism facilities 3. Radiation protection 4. Underground protective engineering 4. High temperature resistance 5. Transportation infrastructure 5. Fast construction Technical Indicators

GB/T50038 Design Code for Civil Air Defense Engineering

Minimum protective thickness of top plate with upper structure (mm)

City altitude (m) Dose limit (Gy) Nuclear weapon resistance level Level 4 Level 4B Level 5 Level 6, 6B ≤200 0.1 970 820 460 250 0.2 860 710 360 >200 and ≤1200 0.1 1010 860 540 0.2 900 750 430 >1200 0.1 1070 930 610 0.2 960 820 500 Minimum protective thickness of top plate without upper structure (mm)

City altitude (m) Dose limit (Gy) Nuclear weapon resistance level Level 4 Level 4B Level 5 Level 6, 6B ≤200 0.1 1150 1000 640 250 0.2 1040 890 540 >200 and ≤1200 0.1 1190 1040 720 0.2 1080 930 610 >1200 0.1 1250 1110 790 0.2 1140 1000 680 JGJ/T472 Design Code for Reinforced Concrete Structures

Structure Type Seismic fortification intensity 6 degrees 7 degrees 8 degrees 0.10g 0.15g 0.20g 0.30g Frame 50 40 40 35 30 Special-shaped column frame 24 21 15 12 - Frame-shear wall 110 100 100 85 65 Special-shaped column frame-shear wall 45 40 30 25 15 Shear wall Full-height shear wall 120 100 100 85 65 Partial frame shear wall 100 85 85 65 40 Core tube Frame-core tube 130 110 110 85 75 Tube-in-tube 150 130 130 100 85 Column-shear wall 70 60 60 45 30 Application Scenarios

Military and defense projects High-risk facility protection Public counter-terrorism facilities Underground protective engineering Transportation infrastructure Usage

Preparation

Before grouting, the surface of the base in contact with the grouting material should be cleaned and cleaned, and the surface of the base concrete should be fully moistened 24 hours before grouting. One hour before grouting, remove the accumulated water.

Grouting material preparation

1. When mixing cement-based grouting materials, add water according to the water consumption specified in the product qualification certificate. Weigh the water first, then pour the grouting material into the water and stir.

2. Before grouting, select (but not limited to) the following equipment and instruments according to the characteristics of on-site grouting: mechanical stirring; forced concrete mixer; manual stirring; hand-held drill stirrer. The mixing time is 3-5 minutes, and the mixing location should be close to the grouting material location. If there are a lot of bubbles on the surface, let it stand for 3 minutes before pouring, or you can tap the formwork appropriately.

3. Grouting should be continuous, and the mixed grouting material should be used up within 30 minutes.

4. Vibration is strictly prohibited during grouting, appropriate insertion can be used, and the formwork can be tapped appropriately at the formwork.

Curing of grouting material

1. After grouting, the exposed parts should be sprayed with curing agent or covered with plastic film in time, and covered with wet grass bags to keep them moist.

2. When using plastic film covering, the exposed surface of the grouting material should be covered tightly to keep the condensed water inside the plastic film.

3. When the surface of the grouting material is inconvenient to water, a curing agent can be sprayed.

4. The watering curing time should be no less than 7d, and the number of watering times should keep the grouting material moist.

Precautions

1. According to the weather forecast. Avoid outdoor construction on rainy days. If the working surface is rained in the middle, a rain cloth should be set up in time. If rainwater is poured in, rework should be carried out in time.

2. The standard water-cement ratio for this product is 0.12-0.14. The water-cement ratio is a crucial component of cement grout; arbitrarily adding water will affect product performance.

3. Use specialized machinery for forced, rapid mixing for 3-4 minutes to prevent uneven mixing and the inclusion of unmixed materials, which can affect the later strength of the cement grout. Do not mix manually on the ground with shovels.

4. Pay attention to temperature changes before construction. Temperature affects the initial and final setting time and fluidity of the cement grout. The recommended construction temperature is 5-35℃. For construction in sub-zero temperatures, please inform our company in advance; we have corresponding high-early-strength, freeze-thaw resistant products.

5. Mechanical vibration is strictly prohibited during construction; however, channeling is acceptable. This prevents stratification and bleeding of the cement grout.

6. The dry density of the cement grout is 2400 KG/m³. Calculate the required amount based on the cubic footage of the project; mix only what is needed! Avoid mixing a large quantity that will go unused. Leftover material must not be remixed with fresh grout.

7. Strictly prohibit the arbitrary addition of any chemical substances on-site, as this will alter the product performance of the cement grout.

8. This product must be protected from moisture or rain. It must pass inspection after the expiration date before reuse.

Factory Strength

Qualification

Message

Please provide the following valid information, and we will contact you as soon as possible.