PRODUCTS

C70 Tunnel Vault Grouting Material

Main business:Building, infrastructure, industrial, mining, marine engineering, military engineering, expressway, tunnel, bridge, concrete repair, installation of large-scale mechanical equipment, wind power equipment, foundation bolt fixing, etc. High-performance, early-strength, micro-expansion, self-compacting, large-flow leveling, rapid repair cement grouting material

- Commodity name: C70 Tunnel Vault Grouting Material

- Description

-

Specifications 25kg/bag Model C70 Packaging Material Three paper and one film Shipping Method Jumbo bags Shipping Time Consult the freight forwarder Shelf Life Six months FOB Price $350/ton MSDS Yes Payment Method Telegraphic Transfer Storage Keep away from rain or moisture Application Scenarios Features: 1. Fill and support gaps 1. Pumpable 2. Consolidate loose surrounding rock 2. Self-flowing 3. Waterproof, leak-proof, and anti-seepage 3. Micro-expansion 4. Control settlement deformation 4. Slow-setting 5. Repair damaged areas 5. Self-compacting Performance Parameters

Category Class I Class II Class III Class IV Maximum Aggregate Size (mm) <4.75 <4.75 and ≤25 Truncated Cone Flowability (mm) Initial Value - ≥342 ≥355 ≥655 30min - ≥338 ≥350 ≥555 Flow Cone Flowability (s) Initial Value ≤35 - - - 30min ≤50 - - - Vertical Expansion Rate (%) 3h 0.1~3.5 0.16 0.14 0.1~3.5 Difference between 24h and 3h expansion values 0.03~0.06 0.03 0.06 0.03~0.06 Compressive Strength (Mpa) 1d ≥15 ≥30 ≥30 ≥40 3d ≥30 ≥50 ≥60 ≥70 28d ≥50 ≥65 ≥80 ≥90 Chloride Ion Content (%) <0.1 Bleeding Rate (%) 0 Application Scenarios

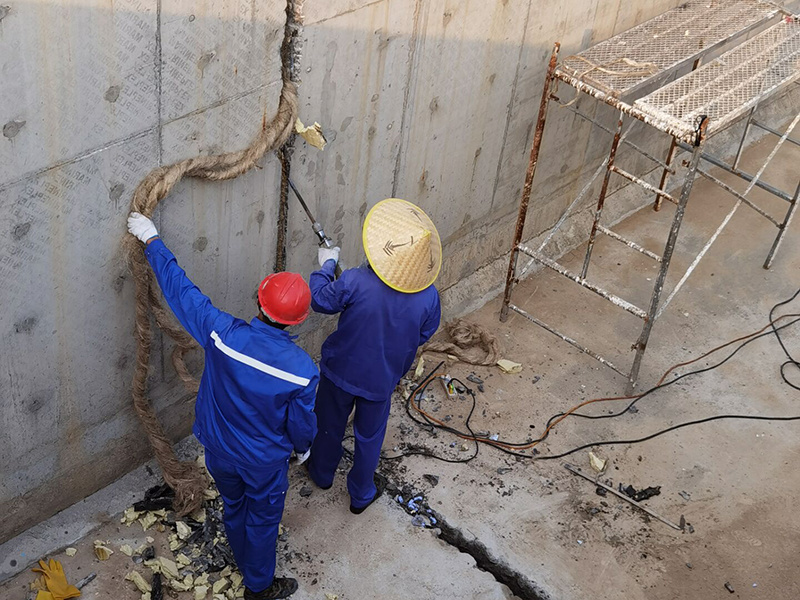

Fill and support gaps Consolidate loose surrounding rock Waterproof, leak-proof, and anti-seepage Control settlement deformation Repair damaged areas Usage

Preparation

Before grouting, the surface of the base in contact with the grouting material should be cleaned and roughened. The surface of the base concrete should be fully wetted 24 hours before grouting, and any accumulated water should be removed 1 hour before grouting.

Grout Preparation

1. When mixing cement-based grouting materials, add water according to the water content specified in the product certificate. Weigh the water first, then pour the grouting material into the water and stir.

2. Before grouting, select (but not limited to) the following equipment and instruments according to the characteristics of on-site grouting: mechanical stirring; forced concrete mixer; manual stirring; hand-held drill stirrer. The mixing time is 3-5 minutes, and the mixing location should be close to the grouting material location. If there are many bubbles on the surface, let it stand for 3 minutes before pouring, or tap the formwork appropriately.

3. Grouting should be continuous, and the mixed grouting material should be used up within 30 minutes.

4. Vibration is strictly prohibited during grouting. Appropriate tamping can be performed, and the formwork can be tapped appropriately at the formwork.

Grout Curing

1. After grouting, the exposed parts should be sprayed with a curing agent or covered with plastic film, and covered with wet straw bags to keep them moist.

2. When using plastic film to cover, the exposed surface of the grouting material should be covered tightly, and condensation water should be maintained inside the plastic film.

3. If the surface of the grouting material is inconvenient to water, a curing agent can be sprayed.

4. The water curing time should be no less than 7 days, and the number of watering times should keep the grouting material moist.

Precautions

1. According to the weather forecast. Avoid outdoor construction on rainy days. If the working surface is rained on during construction, cover it with a rain cloth immediately. If rainwater is poured in, rework is required.

2. The standard water content of this product is 0.12-0.14. The water-cement ratio is an important part of cement grout. Arbitrary addition of water will affect the product performance of cement grout.

3. Use special mechanical forced rapid mixing for 3-4 minutes to prevent uneven mixing and the inclusion of unmixed material, which will affect the later strength of the cement grout. Do not manually mix with a shovel on the ground.

4. Pay attention to temperature changes before construction. Temperature affects the initial and final setting time and fluidity of the cement grout. The recommended construction temperature is 5-35℃. For low-temperature construction below zero, please inform our company in advance. We have corresponding high-early-strength and freeze-thaw resistant products.

5. Mechanical vibration is strictly prohibited during construction; however, channeling is allowed. Prevent stratification and bleeding of the cement grout.

6. The dry density of the cement grout is 2400KG/m³. Calculate the required amount based on the cubic meter of the project. Mix only the amount needed! Strictly prohibit mixing a large amount that will not be used to avoid waste. Leftover material is strictly prohibited from being remixed with the grout for reuse.

7. Strictly prohibit the arbitrary addition of any chemical substances on-site to alter the product performance of the cement grout.

8. This product must be protected from moisture or rain. It can only be reused after passing the quality inspection after the expiration date.

Factory Strength

Qualification

Message

Please provide the following valid information, and we will contact you as soon as possible.